Anchor for fixing thermal insulation with elongated expansion zone and plastic nail LZK-P

- Trademark: EasyFix

- Country of origin: Ukraine

Цена: 0.00 грн.

- Meets the requirements of DSTU B V.2.6-36: 2008 and ETAG014

- Extended thrust zone - 80mm

- The shape of the expansion zone has been optimized for better installation in building materials

- The perforated surface of the disc facilitates plaster work and guarantees high quality adhesion to the plaster.

Code | Diameter (drilling) nailed-in plastic anchor, mm | Nailed-in plastic anchor length, mm | Pressure disk diameter, mm | Thrust length, mm | Minimum installation depth, mm | Maximum thermal insulation thickness, mm | Minimum drilling depth for through installation, mm | Quantity per package, pcs. |

LZK-P 10 80 | 10 | 80 | 58 | 50 | 50 | 30 | 90 | 100 |

LZK-P 10 100 | 10 | 100 | 58 | 50 | 50 | 50 | 110 | 100 |

LZK-P 10 120 | 10 | 120 | 58 | 50 | 50 | 70 | 130 | 100 |

LZK-P 10 140 | 10 | 140 | 58 | 50 | 50 | 90 | 150 | 100 |

LZK-P 10 160 | 10 | 160 | 58 | 80 | 50 | 110 | 170 | 100 |

LZK-P 10 180 | 10 | 180 | 58 | 80 | 50 | 130 | 190 | 50 |

LZK-P 10 200 | 10 | 200 | 58 | 80 | 50 | 150 | 210 | 50 |

Recommended for plaster facades.

For fixing such heat-insulating materials:

- Styrofoam

- Styropolistirol

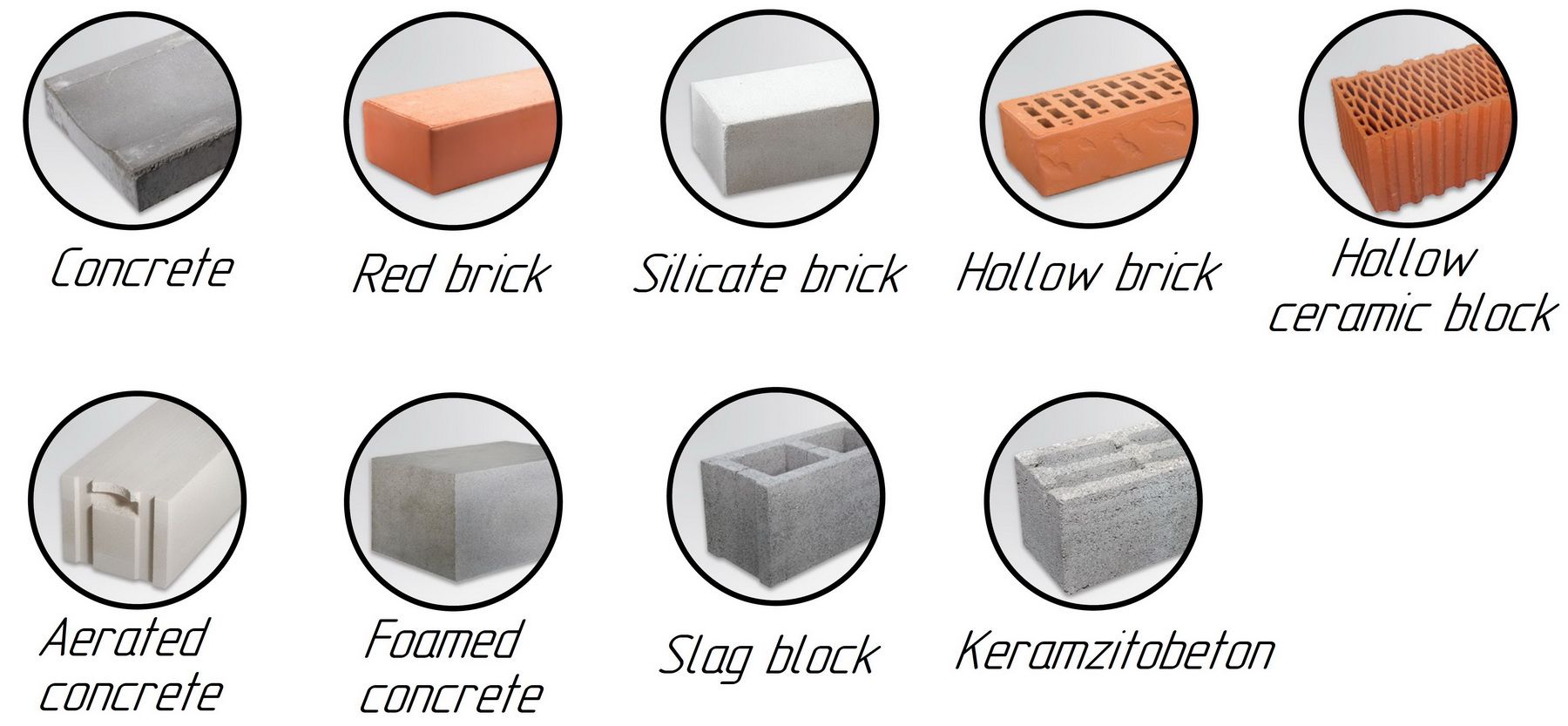

Foundation materials

| Characteristics | |

| Length of spacing zone, mm | 80 |

| Nail material | plastic |

| For fixing foam | yes |

| For plaster facade | yes |

- Type of installation - push-through installation

- For installation in aerated concrete, foam concrete, shell rock and ceramic hollow block, it is recommended to use only drilling without impact

- Recommended mounting parameters:

- minimum base thickness - 100 mm

- minimum center distance between dowels - 100 mm

- minimum distance from the edge of the base to the dowel - 100 mm

- Installation instructions:

- 1. Drill a hole

- 2-3. Hammer to the stop, hitting the body of the dowel with a hammer

- 4-5. Hammer the spacer (nail) flush with the dowel