Anchor for fixing thermal insulation with zinc-plated steel screw LX/H

- Trademark: Starfix

- Country of origin: Poland

Цена: 0.00 грн.

- ITB technical assessment

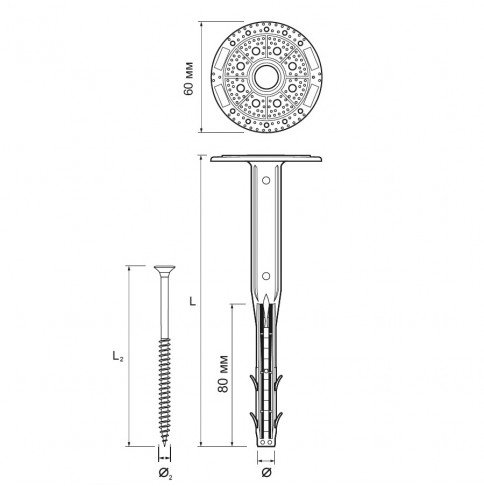

- Dowel with an extended four-sided expansion zone, for better installation in porous and hollow building materials

- One screw is used for different dowel lengths (universal screw 6 × 100)

- Meets the requirements of DSTU B V.2.6-35: 2008, DSTU B V.2.6-36: 2008 and ETAG014

- In contrast to the dowel for fixing thermal insulation with a metal nail, it does not destroy the walls in the hollow base material when hooking the screw

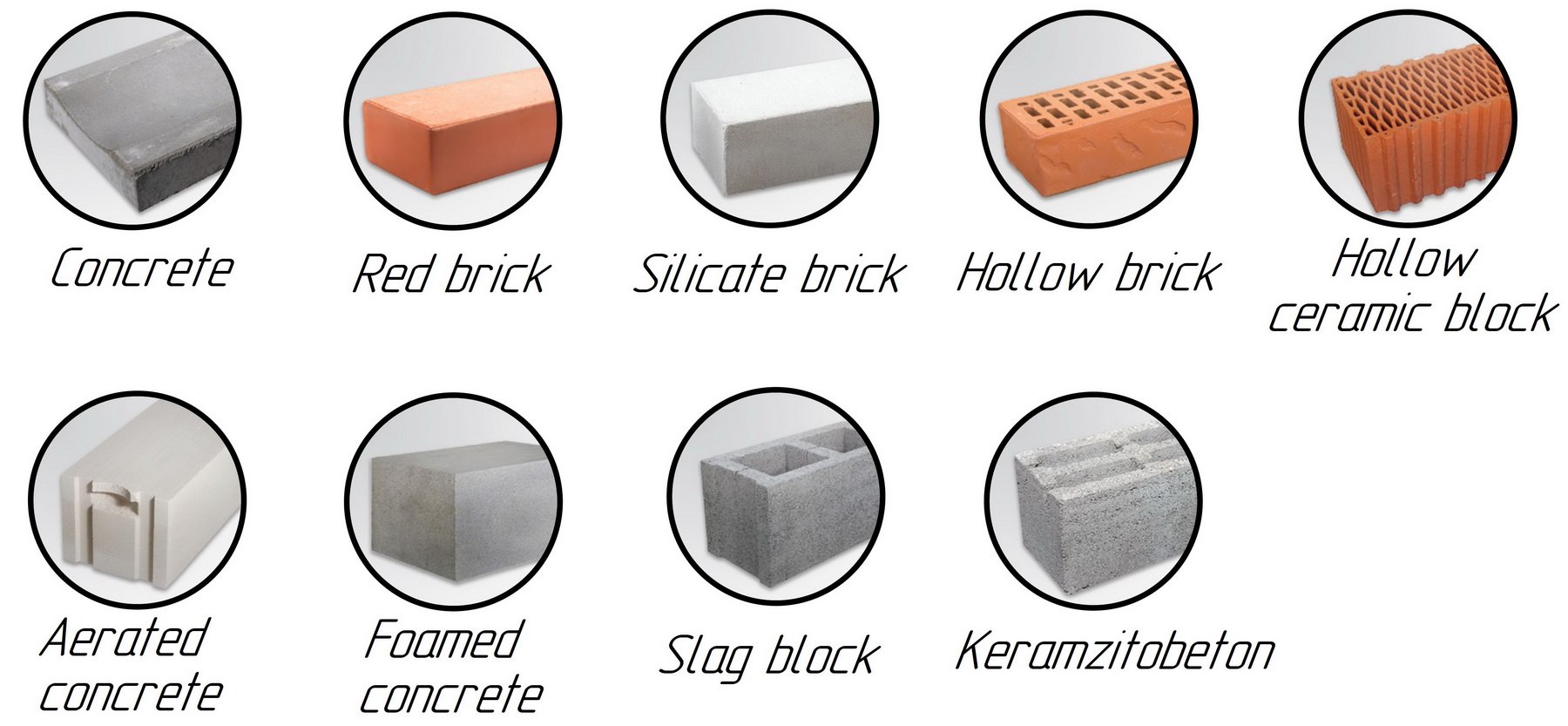

- Universal for use in all base materials

- The perforated surface of the disc facilitates plaster work and guarantees high quality adhesion to the plaster.

- Retains properties over a wide temperature range

Code | Diameter (drilling) nailed-in plastic anchor, mm | Nailed-in plastic anchor length, mm | Pressure disk diameter, mm | Thrust length, mm | Minimum installation depth, mm | Maximum thermal insulation thickness, mm | Minimum drilling depth for through installation, mm | Quantity per package, pcs |

LX 10 160 H | 10 | 160 | 60 | 80 | 601)/402) | 1001)/1202) | 170 | 100 |

LX 10 180 H | 10 | 180 | 60 | 80 | 601)/402) | 1201)/1402) | 190 | 100 |

LX 10 200 H | 10 | 200 | 60 | 80 | 601)/402) | 1401)/1602) | 210 | 100 |

LX 10 220 H | 10 | 220 | 60 | 80 | 601)/402) | 1601)/1802) | 230 | 100 |

LX 10 240 H | 10 | 240 | 60 | 80 | 601)/402) | 1801)/2002) | 250 | 100 |

1) for all base materials except hollow ceramic bricks

2) for hollow ceramic bricks

Estimated pull-out load:

from concrete - 1.5 kN

from solid red brick - 1.5 kN

from solid silicate brick - 1.5 kN

from a hollow ceramic block - 1.1 kN

from aerated concrete - 0.6 kN

from concrete - 1.5 kN

from solid red brick - 1.5 kN

from solid silicate brick - 1.5 kN

from a hollow ceramic block - 1.1 kN

from aerated concrete - 0.6 kN

Recommended for plaster facades and facades with a ventilated air layer.

For fixing such heat-insulating materials:

- Styrofoam

- Mineral wool

- Styrofoam

- Glass wool

Foundation materials

| Characteristics | |

| Length of spacing zone, mm | 80 |

| Nail material | self-tapping screw |

| For fixing mineral wool | yes |

| For fixing foam | yes |

| For plaster facade | yes |

| For ventilated facade | yes |

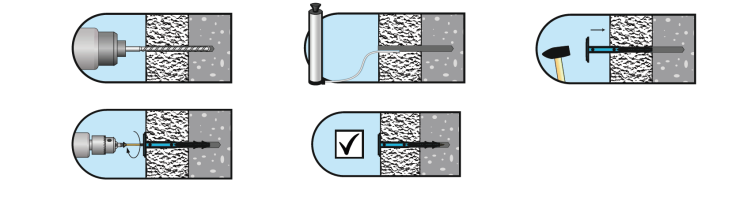

- Type of installation - push-through installation

- For installation in aerated concrete, foam concrete, shell rock and ceramic hollow block, it is recommended to use only drilling without impact

- Recommended mounting parameters:

- minimum base thickness - 100 mm

- minimum center distance between dowels - 100 mm

- minimum distance from the edge of the base to the dowel - 100 mm

- Installation instructions: